This involves interactions between a business and its customers. It's about meeting customers' needs and resolving their problems. Effective customer service is crucial.

This involves interactions between a business and its customers. It's about meeting customers' needs and resolving their problems. Effective customer service is crucial.

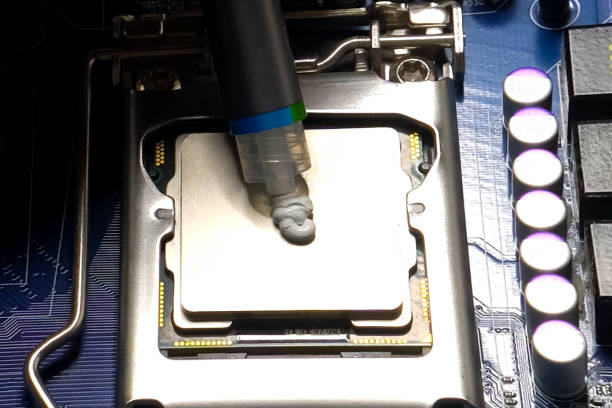

Thermally conductive adhesives are unique bonding materials designed to remove heat efficiently. These materials effectively bond things together while also allowing heat to transfer quickly. Their unique composition makes them essential for quick heat dissipation. We have Thermal Adhesives in many chemistries such as PU, Silicone, Epoxy, and others. They are commonly used across industries like automotive and electronics where heat removal is crucial. Whatever our customers' niche needs Sagar Thermal will provide a solution. Let’s get into the details!

There are times when components require stable bonding alongside optimal heat transfer capabilities. Thermally conductive adhesives meet these needs, making them crucial in applications involving high-stress environments where regular adhesives may underperform regarding thermal conductivity or adhesion strength. They enable effective thermal management solutions, essential for industries like electronics, automotive, aerospace, and manufacturing.

Let's explore the core features of thermally conductive adhesive

Offering versatility in bonding diverse materials, these adhesives have a wide range of applications.

The adhesive conducts heat well and demonstrates solid, long-lasting bonds. It performs reliably, even under challenging conditions.

They excel at transferring heat efficiently, because of their impressive thermal conductivity. This property helps prevent overheating.

These adhesives provide superb electrical insulation and thermal conductivity, ensuring the safety and reliability of bonded components.

Being solvent-free and odorless makes them environmentally friendly and safe for use in various settings.

Their appropriateness for weight-conscious applications, particularly in sectors like aerospace and automotive, is directly attributed to their lightweight composition.

These components have obtained the UL94-V0 flammability certification, adhering to strict safety guidelines. This capability makes them suitable for environments requiring exceptional fire protection measures.

These adhesives sustain their efficacy for approximately six months, ensuring their reliability over prolonged durations.